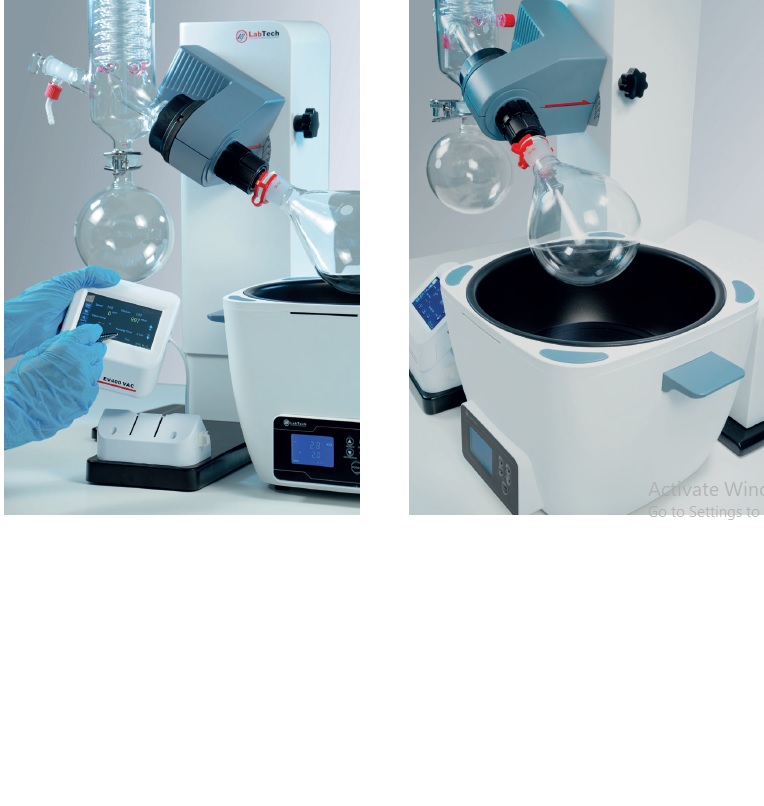

Rotary Ivaporator

Price 512000.0 INR/ Piece

MOQ : 1 Piece

Rotary Ivaporator Specification

- Display Type

- LCD Display

- Power Supply

- Electric

- Usage

- Digital rotation speed control and temperature display ensure accurate and stable unit operations Trouble free operation and long lifetime PTFE seal loop ensures excellent elasticity and resistance at high temperature acid/ solvent corrosion Online sample addition by PTFE tube ensures high effi ciency and easy operation Automatic lift-up protection in case of electric power failure Pre-loaded solvents library Availability of both vertical and diagonal column

- Size

- Standard

- Color

- White

- Voltage

- 220 Volt (v)

- Material

- Stainless Steel

- Application

- Solvent recycling Solvent distillation Powder drying Chemical synthesis Extraction Research Active agent concentration Vacuum distillation of sensitive substances Liquid mixture separation

- Warranty

- 1 Year

Rotary Ivaporator Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30 Days

About Rotary Ivaporator

The LabTech evaporation solutions introduce a new concept in routine distillation/evaporation processes:

safety, effi ciency and durability to support the lab user work!

With an innovative and ergonomic design, the EV series rotary evaporators include digital display to monitor

and control rotation speed and temperature, motorized vertical lift, evaporation fl asks, on line sample adding

through PTFE tube and can be completed with the LabTech vacuum pump and cooling accessories to reach

top effi ciency of process.

The stand alone heating bath guarantees maximum safety in operations and easy maintenance.

MAIN APPLICATIONS

Solvent recycling

Solvent distillation

Powder drying

Chemical synthesis

Extraction

Research

Active agent concentration

Vacuum distillation of sensitive substances

Liquid mixture separation

Complete Package

Programmable operations

Anticorrosion sealing system

Integrated vacuum control

Maximum safety

Quite operation

Excellent price/performance ratio

A Solution for Versatile Industrial Applications

Ideal for research laboratories and industrial scale operations, this rotary evaporator streamlines processes like solvent distillation, powder drying, liquid mixture separation, and extraction. Its standard size and automatic operation ensure compatibility and efficiency, making it a critical tool for chemists and researchers.

Reliable and Durable Performance

Constructed with high-grade stainless steel and equipped with PTFE seal loops for resilience, the rotary evaporator promises trouble-free operation and a long service life. The automatic lift-up system and LCD display ensure continuous monitoring and enhanced safety throughout its use.

User-Friendly Automated Features

Digital speed control, precise temperature display, and an extensive solvents library help simplify complex procedures. The automatic operation, online sample addition, and availability of both vertical and diagonal columns provide flexibility, efficiency, and ease of use in various industrial settings.

FAQs of Rotary Ivaporator:

Q: How does the rotary evaporator ensure accurate and stable operations?

A: The rotary evaporator uses digital rotation speed control and an LCD temperature display, allowing users to set and monitor both parameters with high accuracy, ensuring stable and reliable operation during experiments and industrial processes.Q: What safety features are included in this rotary evaporator?

A: This model features automatic lift-up protection, which automatically raises the evaporating flask in the event of a power failure, preventing potential damage or spillage and optimizing safety during use.Q: Where is the rotary evaporator typically used?

A: This rotary evaporator is widely used in research labs, chemical industries, and for industrial processing in areas such as solvent recycling, active agent concentration, chemical synthesis, vacuum distillation, and the separation of liquid mixtures.Q: When should I use a rotary evaporator over traditional distillation methods?

A: A rotary evaporator is preferable when gentle, efficient separation is required, especially for heat-sensitive solvents or compounds. Its vacuum system allows for lower boiling points, minimizing thermal degradation and speeding up the process.Q: What makes the rotary evaporator durable and resistant to corrosion?

A: The evaporators construction employs stainless steel and a PTFE seal loop, both known for their durability and exceptional resistance to high temperatures, acids, and solvent corrosion, ensuring a long lifetime and minimal maintenance.Q: How does the online sample addition system benefit operation?

A: Online sample addition via a PTFE tube allows samples to be introduced into the system seamlessly during operation, improving efficiency and ease of use while reducing downtime for the operator.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Laboratory Instruments Category

Rotary Evaporator

Price 512000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : White

Application : Laboratory

Display Type : LCD Display

Power Supply : Electric

FREEZE DRYER & COOLING TRAP

Price 1150000.0 INR / Number

Minimum Order Quantity : 1 Number

Color : White

Application : Laboratory

Display Type : Digital

Power Supply : Electric

MICRO/MULTIPURPOSE CENTRIFUGES

Price 250000.0 INR / Number

Minimum Order Quantity : 1 Number

Color : White

Application : Hospital, Laboratory

Display Type : Digital

Power Supply : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS