FREEZE DRYER & COOLING TRAP

Price 1150000.0 INR/ Number

MOQ : 1 Number

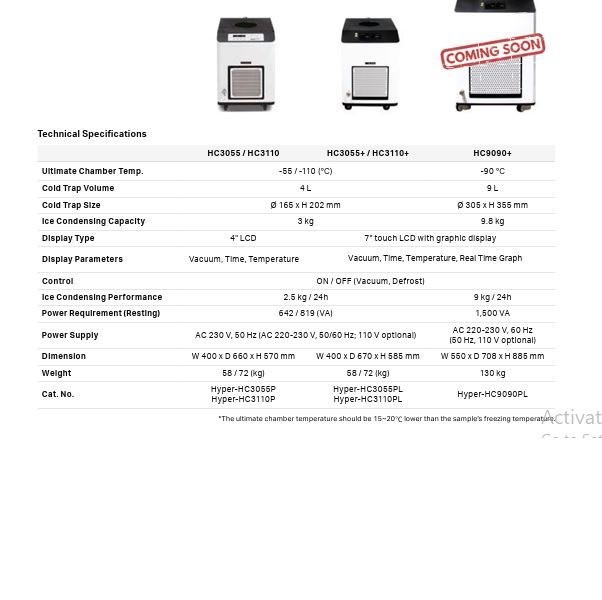

FREEZE DRYER & COOLING TRAP Specification

- Display Type

- Digital

- Power Supply

- Electric

- Size

- Standard

- Color

- White

- Application

- Laboratory

- Warranty

- 1 Year

FREEZE DRYER & COOLING TRAP Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

About FREEZE DRYER & COOLING TRAP

The freeze drying process consists of three stages: pre-freezing, primary drying, and secondary drying. Pre-freezing: Since freeze drying is a change in state from the solid phase to the gaseous phase, material to be freeze dried must first be adequately pre-frozen. The method of pre-freezing and the final temperature of the frozen product can affect the ability to successfully freeze dry the material. Rapid cooling results in small ice crystals, useful in preserving structures to be examined microscopically, but resulting in a product that is more difficult to freeze dry. Slower cooling results in larger ice crystals and less restrictive channels in the matrix during the drying process. Products freeze in two ways, depending on the makeup of the product. The majority of products that are subjected to freeze drying consist primarily of water, the solvent, and the materials dissolved or suspended in the water, the solute. Most samples that are to be freeze dried are eutectics which are a mixture of substances that freeze at lower temperatures than the surrounding water. When the aqueous suspension is cooled, changes occur i n the solute concentrations of the product matrix. And as cooling proceeds, the water is separated from the solutes as it changes to ice, creating more concentrated areas of solute. These pockets of concentrated materials have a lower freezing temperature than the water. Although a product may appear to be frozen because of all the ice present, in actuality it is not completely frozen until all of the solute in the suspension is frozen. The mixture of various concentration of solutes with the solvent constitutes the eutectic of the suspension. Only when all of the eutectic mixture is frozen is the suspension properly frozen. This is called the eutectic temperature. It is very important in freeze drying to pre-freeze the product to below the eutectic temperature before beginning the freeze drying process. Small pockets of unfrozen material remaining in the product expand and compromise the structural stability of the freeze dried product. The second type of frozen product is a suspension that undergoes glass formation during the freezing process.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Laboratory Instruments Category

Rotary Ivaporator

Price 512000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Electric

Color : White

Display Type : LCD Display

Size : Standard

Rotary Evaporator

Price 512000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Electric

Color : White

Display Type : LCD Display

Size : Standard

MICRO/MULTIPURPOSE CENTRIFUGES

Price 250000.0 INR / Number

Minimum Order Quantity : 1 Number

Power Supply : Electric

Color : White

Display Type : Digital

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS